avancé embroidery machine troubleshooting

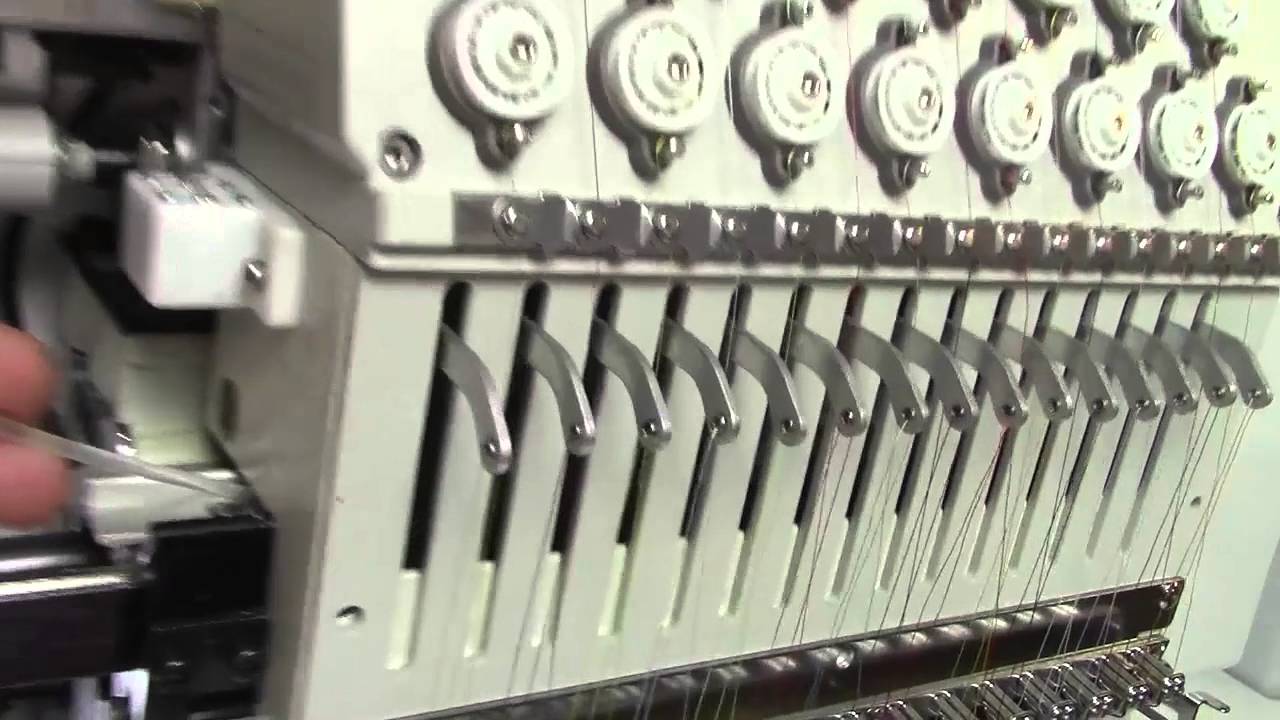

Confirm and turn cancel embroidery to confirm embroidery which indicates the machine has entered Embroidery Ready Status. It is prevailing to have needle breaks.

Avance Multihead Embroidery Machine Maintenance Youtube

22 x 14 560mm x 360mm.

. Do this using the keys on the control panel 3. A bobbin designed specifically for this machine is not used. You can call or contact Brother but they will not help you with machine problems.

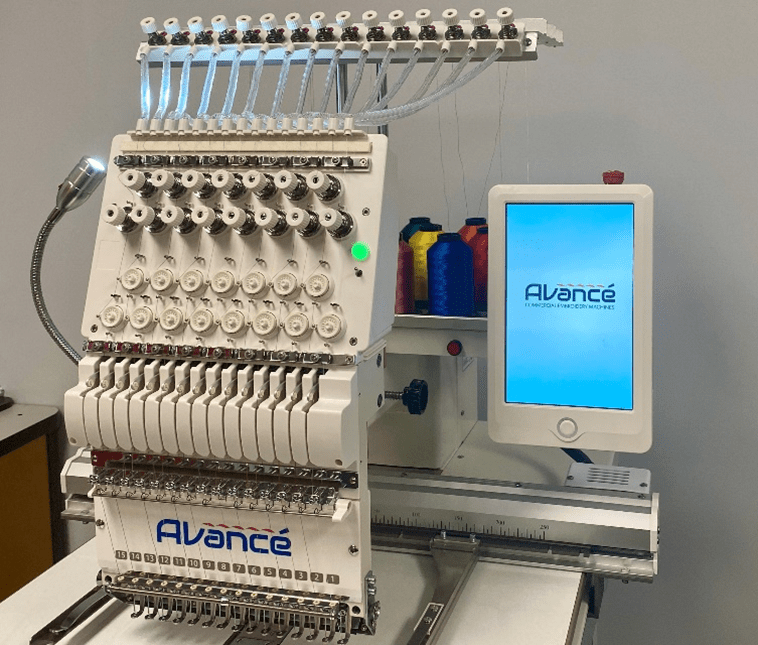

We provide one location for all of your embroidery needs. You can cluster 2 3 6 units and turn them into an incredibly versatile multi-head embroidery system. The tiny slot on the thread spool can catch your thread and prevent it from flowing properly.

Select needle seven 7Do this using the keys on the control panel 3. There may even be a certain sequence to follow to get your machine back on track. Select needle six 6.

325 Absolute origin could not be detected on the X Find faulty origin sensor and adjust or replace. Remove the loose thread. Re-thread both top bobbin thread.

We provide on-site Commercial Embroidery Machine Repair Service and Training on most brands of commercial embroidery machines. A hint window will display on the screen for user to. Recording of a Live Webinar on setting and troubleshooting tensions in the Avance commercial embroidery machine series from ColDesiFebruary 2016.

This referral is in the contracts that Brother has with their associate stores. Basic Machine Embroidery Troubleshooting Help Use The Correct Needles Be sure to select the correct needle for your machine home machines use flat shank needles and. The thread is loose in the hook area or the hook does not rotate smoothly.

And also it is one of the first embroidery companies that developed computerized embroidery technology. A warped needle can go down on the presser foot which will cause it to break. The needle may be too small for the thread weight.

Puckering is when the fabric around your embroidery bubbles up and puckers making the whole thing look like a wrinkled bubbly mess. There are two reasons your embroidery is puckering and good news is they are both super easy to fix. The thread quality is too weak due to age of thread.

The Avancé 1501C is a 15 needle SINGLE head embroidery machine but one with some multi-head advantages. Power the machine on and allow it to continue to the main drive screen. Firmly set the fabric in the embroidery frame so that it is taut.

Answer yes or no questions and follow video instructions to the most common issues. Welcome to AJs Stitchin Time. We have been in business since 2007 as an in-home embroidery business and began repairing servicing embroidery machines in 2008.

We provide on-site Commercial Embroidery Machine Repair Service and Training on most brands of commercial embroidery machines. Select needle six 6. One of the most common sewing machine problems is the sewing machine creating a loopy knotted mess of thread which stops the machine from sewing and leaves a knotted mess of loopy thread that is miserable to rip out.

Tech Talk How to Stop Ruining Hats Avancé Embroidery MachineLearn more here. Remove the needle plate and bobbin case. Always use good quality thread.

Avancé 1501C Embroidery Machine. At this time the machine will not work even when user presses the start key. Check to see if you are using the appropriate needle size.

The thread quality is poor. Grab the seam ripper and calmly remove the faulty stitches. As the name suggests needle breaks occur if the needle is bent loose small or if the stitch position is not matching the surface.

I was able to graduate from the. BEFORE you start stitching. Your sewing machine will thank you and you will have less headaches.

Garment Puckering If you shirt looks great before you remove it from the hoop but puckers after you take it out of the. Get Your Custom Quote. Melco an embroidery technology and direct sales organization was built in 1972.

Do this by loosening each of the two 2 flathead screws with an offset screwdriver provided in the machines toolkit 3. The problem is common for machine embroidery. If user selects the machine will stay at Embroidery Cancel Status.

If the Troubleshooting steps didnt help ColDesi has an advanced tech support ticketing system we use to make sure everyone gets the help they need as quickly as possible. Remove the needle plate and bobbin case. Basic Machine Embroidery Troubleshooting Help Use The Correct Needles Be sure to select the correct needle for your machine home machines use flat shank needles and.

Believe it or not the solution is very simple. Check that your thread isnt getting caught up or snagging on anything as if flows through your machine. AJs Stitchin Time provides on-site Commercial Embroidery Machine Repair Service and Training on most brands of machines.

Remove the bobbin case. The basic troubleshooting for these problems is to insert a new needle. 32F Hidden Error Make sure machine has at least version BD or later.

I began working on embroidery machines in 2008. Be sure the bobbin thread clicks into bobbin tension. Make sure that your thread cone doesn not slide off the spool pin if the holder is horizontal.

Try to re-thread your machine. They will direct you to your nearest dealer for support of any kind. Welcome to AJs Stitchin Time.

Remove any knots or tangles. Power the machine on and allow it to continue to the main drive screen. Bobbin thread not in the bobbin tension.

In commercial embroidery one thing is inevitablethread problems will arise. Or Y axis Cap machine origin search error. The way the embroidery machine is threaded.

The Avancé 1501C 2020 from ColDesi has tons of NEW features and the 3 things our customers ask for every day. The bobbin too has its own tension. Use the Troubleshooter below.

While re-threading make sure you hold the thread very tight and it doesn not have the slightest chance to loop anywhere. Giving you the ability to handle large and small orders. If the bobbin thread is not in the its tension the stitch will look unbalanced.

Polyester embroidery threads are strong and resistant to snapping but breaks. Do this by loosening each of the two 2 flathead screws with an offset screwdriver provided in the machine s toolkit Timing for HCS-1201. Melco company is committed to the development of commercial embroidery machinesIts basis is in the United States.

Pantograms offered a technicians class where they had one of the engineers that help design Toyota embroidery machines teach the class. If problem persists change IMM card.

How To Set Tension Avance 1501c Professional Embroidery Machine Training Youtube

Coldesi Inc Announces The Release Of All New Avance Commercial Embroidery Machine News

Avance Embroidery Machine Archives Coldesi

Avance Cap Embroidery Machine Colman And Company

Avance 1501c Multi Head Embroidery Machine Options Avance Commercial Embroidery Machines

Setting And Troubleshooting Tensions On The Avance 1501c Youtube

Kenmore 158 1913 19130 19131 Sewing Machine Instruction Manual Sewing Machine Instruction Manuals Sewing Machine Instructions Sewing Machine

Avance 1501c Multi Head Embroidery Machine Options Avance Commercial Embroidery Machines

Avance 1501c Multi Head Embroidery Machine Options Avance Commercial Embroidery Machines

![]()

Hard Reset Avance Troubleshooter On Vimeo

Avance Single Head Embroidery Support

How To Make Embroidered Patches Youtube Machine Embroidery Tutorials Embroidered Patches Patches

Avance Multihead Maintenance How To Set Needle Depth Youtube

Avance Single Head Embroidery Support

Avance Single Head Embroidery Support

Avance Single Head Embroidery Support

Avance Training Resolving Common Errors Common Start Up Errors Youtube

Avance Single Head Embroidery Support

Avance 1504 Multihead Commercial Embroidery Machine Demonstration Youtube